Knifeprint CNC waterjet cutting guidelines

At Knifeprint, we not only help you design knives with our easy-to-learn CAD-like Knifeprint editor, we can also help you cut your projects with our custom precision waterjet cutting services. Waterjet cutting is ideal for knifemaking because it is inexpensive, highly accurate and produces excellent cut qualities, making it possible to make intricate shapes or small holes. We can produce cut blanks quickly and cost-effectively while maintaining the highest quality standards. By utilizing Knifeprint to efficiently cut your knife blanks, you’ll have more time to spend designing knives and working on your craft. You can request a quote for this service on any custom designed knife. Depending on your subscription level, you can either use the instant quote service or manually get a quote from knifeprint.com/quote. To get the most out of our waterjet cutting service, here are some guidelines for you to use when designing your knife.

File Formats

CNC machines such as waterjet cutters and waterjet cutters use 2D vector files. Knifeprint currently accepts files for quote and cutting in DXF and SVG format. These files can be produced via the Export option in the Knifeprint Editor. Free users can email these files to [email protected] or simply provide your Project ID number to request a custom quote at knifeprint.com/quote. Pro users can use the instant quote system to automate the quoting process. If you happen to have a design in raster format, you can simply use the Trace Image command under the main menu to load the image into the Knifeprint Editor and trace directly over it with vector geometry.

Scale

Before getting a quote for your knife design and selecting Buy, be sure that your knife is the exact size that you want it. A good way to do this is to export your design as a PDF, then print it to ensure it is the desired size.

Quantity

No matter how many knives you would like cut, please only include one in your DXF per design. Just use the quantity field in the Get Quote dialogue box to let us know how many you’d like, and we’ll take care of nesting any multiple knives here at Knifeprint.

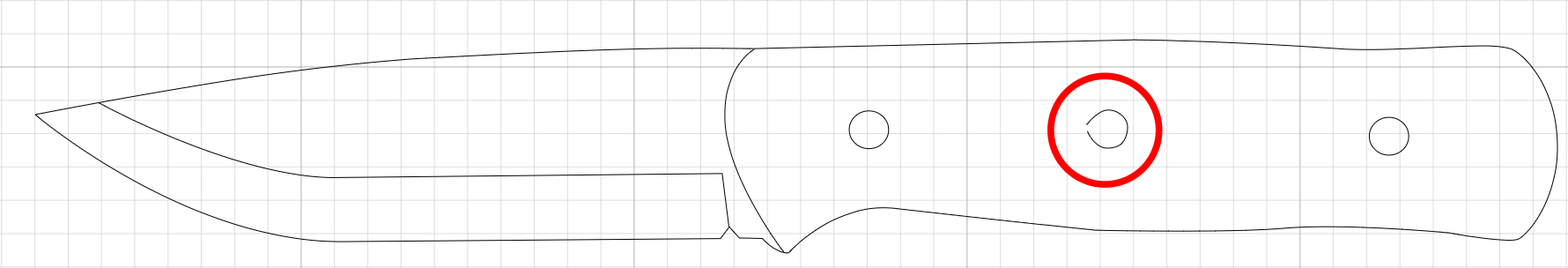

Cutout Size

Any holes to be cut out must have a minimum diameter of 3mm. Please ensure your design adheres to this specification. Shapes or holes with diameters smaller than this may not be accurately cut, or may even be impossible to cut.

Intersecting and Common Lines

Make sure that none of your knife structure overlaps or intersects. This includes the overall knife blade shape, along with any holes. None of these objects should be sharing lines or touching. CNC machines cannot read the lines correctly in these instances and your part will not be cut accurately. All lines and shapes need to be at least 1.5 times the material thickness apart.

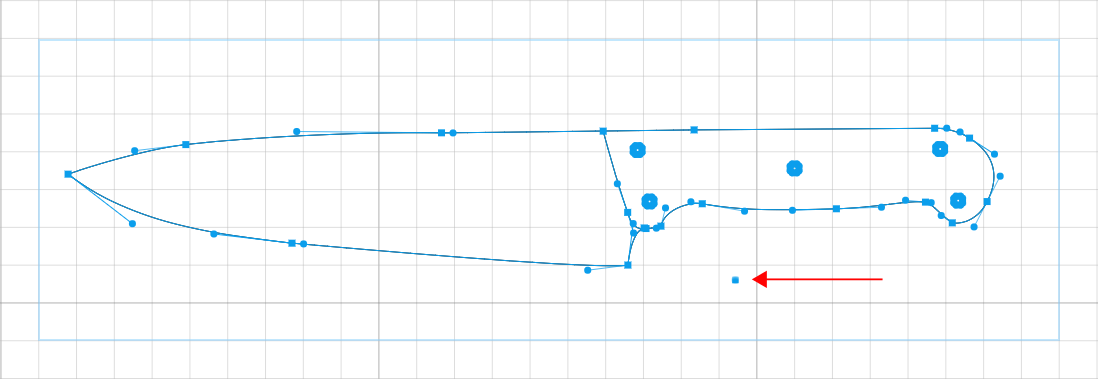

Open Contours

It is important that both your external knife shape, as well as any internal shapes, are fully connected all the way around with no gaps or skips. The waterjet uses these lines as a guide path for cutting. If there are skips or gaps, the waterjet will not cut in these areas.

Bezier Lines

Bezier lines are often used to create the size and location of your blades bevel, as well as the outline of the handle. These bezier lines are not included when you request a quote from the editor, only the holes and the blade outline are included so that the design is compatible with CNC machines. Your knife will come with the uniform thickness specified in the material dropdown menu.

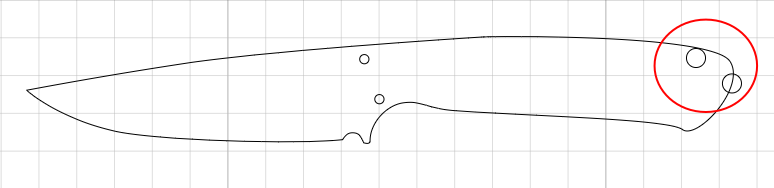

Artifact Nodes

Artifact nodes are single nodes that are sometimes leftover, but unseen after deleting a Bezier line or circle. These nodes can cause problems when we go to prepare your design for waterjet cutting. An easy way to check for and delete artifact nodes is to use the select tool, click and drag a window to select and highlight the hidden nodes and then delete them.

Overlapping Nodes

Make sure there are no overlapping nodes in your design. Overlapping nodes are 2 nodes that have the same position while only one of the two would suffice for the design. While these won't necessarily cause issues, they could cause the cnc machine to make an inaccurate angle or completely reject the design.

Support

Have questions? Need help? Knifeprint is here for you. You can send any questions you have to [email protected].